WEBINAR - The End of the Line Precision Calender Rolls Drive Paper Machine Performance

Published on April 16, 2021

Think your paper machine doesn’t need precision-ground calender rolls?

Think again.

Poor paper machines. Most don’t get a lot of love from their owners.

That’s because paper producers tend to dismiss the need for precisely ground calender rolls in their paper machines. Which is unfortunate.

You might be one of them. When it comes to the quality of your calender roll grinds, you shrug your shoulders and say, “It’s (just) paper. I don’t need the level of precision that you guys are offering me on my calender.”

And we understand your thinking. Yeah, you’re not running something as fine as film or even rubber for that matter. But what about paper strength? You need that, right? Smoothness? Lower fiber costs? We bet those are important boxes to check off. And significantly longer roll life … fewer sheet breaks … consistent product quality? If these are must-haves (and they probably are) then … you actually do need precise-ground calender rolls.

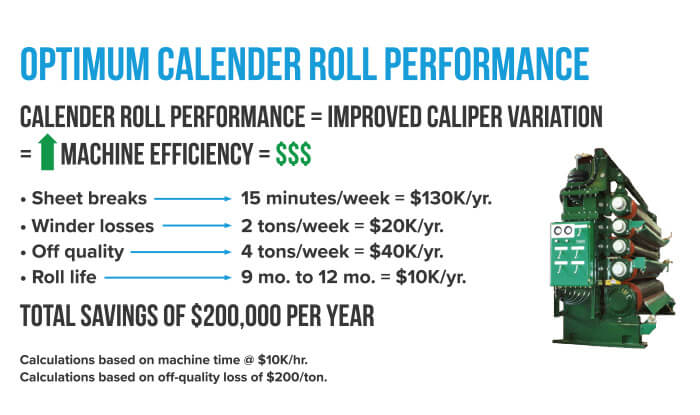

The impact a calender stack has on the performance of a paper machine is not always obvious or widely recognized — but it is far-reaching. And it’s the topic of our latest webinar “The End of the Line: Precision Calender Rolls Drive Paper Machine Performance.” In it, we look at how calender rolls have a hand in influencing many aspects of the product coming off of your machine AND how properly ground and serviced calender rolls pay for themselves and then some — through reduced downtime, material savings, faster run speeds and more.

Using documented findings derived from our 50+ years of servicing the paper industry, we discuss key issues affecting the paper production process and the final product and illustrate how these have a direct correlation to the quality of your serviced calender rolls (commonly misunderstood and undervalued topics like barring and caliper variation). Then through real-life case studies, we share how our precisely ground, perfectly round rolls have yielded substantial cost savings for our clients. For example, we detail how the addition of just our rolls to a facility’s paper machine generated a cost savings of $500,000, by enabling it to run faster while using less fiber.

Lastly, we discuss the benefits to you — and your rolls — of using an experienced grinding professional that focuses solely on roll service. We examine the unique array of mechanical services that PRG provides — including the special attention to pay to the bearings and housings — and their importance to creating top-performing rolls.

Watch “The End of the Line: Precision Calender Rolls Drive Paper Machine Performance” today to fully understand how vital calender rolls are to your paper machine and facility. Click here to view.