Manufacturer sees a bounce in material savings due to precise rubber roll profiles

Published on January 27, 2021

It’s an often-overlooked characteristic of rubber rolls: the profile of the rolls in a rubber calendering process has a direct impact on product variation. We’ve helped many customers understand this issue within their production lines. And, more importantly, we’ve resolved the issue for them with our precise roll services.

This was the case with a rubber calendering facility that recently came to us, asking if we could help solve the problem it was having maintaining product consistency. The variation in its product was adversely affecting the installation of the material in the final end product. The situation needed to be identified and resolved immediately. Adjustments on the machine were not improving quality and many of the settings were being maxed out.

The facility had two calender stacks in its production line process. After reviewing the setup and the actual product variation itself, we shared that the issue was with the inferior quality of the roll grind. Not entirely convinced of our assessment, the manufacturer agreed to have one calender stack ground by PRG to see if a difference in the roll quality grind would in fact yield any improvement. With just one stack ground by PRG, the profile improved. Significantly. The results were so immediate, in fact, that the facility decided to have its second calender stack ground by PRG as well.

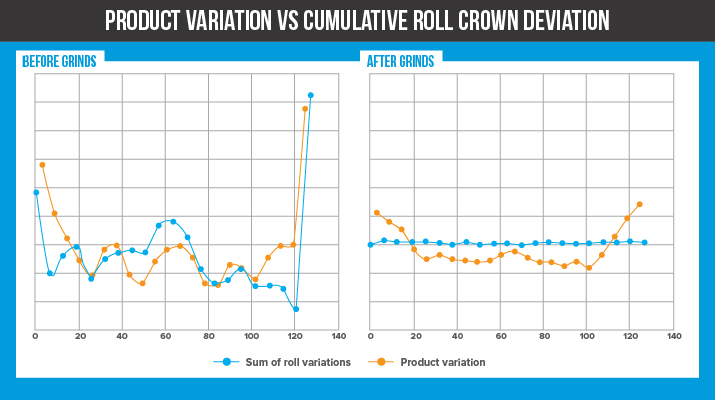

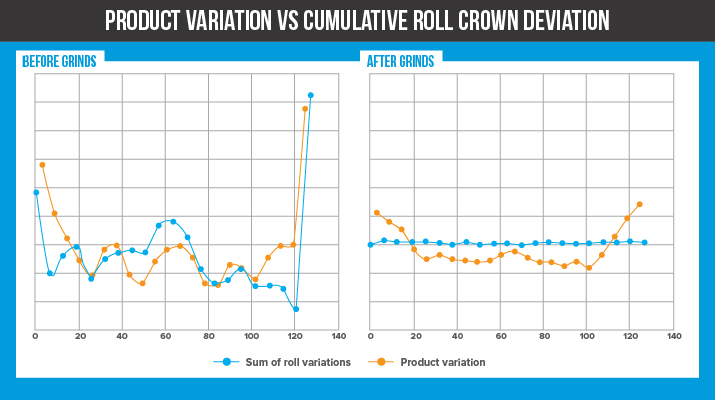

For validated proof, we encourage you to take a look at the two graphs below. They represent the roll profile variation and the product variation before and after both of the calender stacks were ground. The product improvement can be clearly seen as the cross-direction variation was improved by over 25%.

Additionally, the direct effect that the roll’s profile has on the product profile can clearly be seen in this trend. By improving the profile of the roll, the target spec can be moved closer to the lower spec — resulting in huge material savings. In some cases, exceeding hundreds of thousands of dollars. Never underestimate the impact your rolls have on your production line. And the savings you can achieve by having them serviced properly.

This was the case with a rubber calendering facility that recently came to us, asking if we could help solve the problem it was having maintaining product consistency. The variation in its product was adversely affecting the installation of the material in the final end product. The situation needed to be identified and resolved immediately. Adjustments on the machine were not improving quality and many of the settings were being maxed out.

The facility had two calender stacks in its production line process. After reviewing the setup and the actual product variation itself, we shared that the issue was with the inferior quality of the roll grind. Not entirely convinced of our assessment, the manufacturer agreed to have one calender stack ground by PRG to see if a difference in the roll quality grind would in fact yield any improvement. With just one stack ground by PRG, the profile improved. Significantly. The results were so immediate, in fact, that the facility decided to have its second calender stack ground by PRG as well.

For validated proof, we encourage you to take a look at the two graphs below. They represent the roll profile variation and the product variation before and after both of the calender stacks were ground. The product improvement can be clearly seen as the cross-direction variation was improved by over 25%.

Additionally, the direct effect that the roll’s profile has on the product profile can clearly be seen in this trend. By improving the profile of the roll, the target spec can be moved closer to the lower spec — resulting in huge material savings. In some cases, exceeding hundreds of thousands of dollars. Never underestimate the impact your rolls have on your production line. And the savings you can achieve by having them serviced properly.