WEBINAR - Are you running your machine at the optimum settings?

Published on July 27, 2021

Are you running your machine at the optimum settings?

Find out with a Design of Experiment.

Increasing your production line’s efficiency by identifying factors that can reduce material and energy consumption and/or minimize costs and waiting time sounds simple. But we all know it’s not.

Today’s manufacturing machines are more complex than ever. There are so many variables to consider — and it may not always be obvious how one affects another. You may find that altering one component of the process does not always produce the result you were expecting. Sometimes, to achieve one metric, you may be forced to sacrifice another. Or maybe you need to frequently change your machine settings for no apparent reason. It’s frustrating and costly. But it can be resolved … with a design of experiment.

A design of experiment (DOE) is an analysis and statistical tool used to determine the relationship between factors affecting a process and the output of that process. In other words, it’s used to find cause-and-effect relationships. (Increasing A will decrease B but not affect C). With this information, the production process inputs can be properly managed to optimize the output.

In our latest webinar, “Design of Experiment (DOE),” we take a look at this valuable tool, its benefits and how it can help you identify and better control the variables affecting your manufacturing process and product quality. We also show how, with this knowledge, you can determine the best run settings for the machines on your production line.

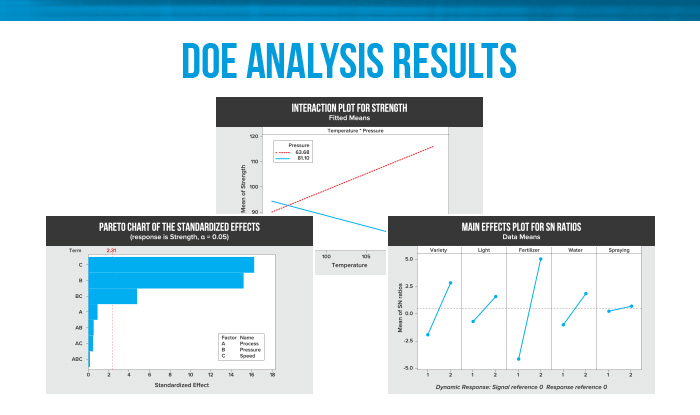

Drawing upon the expertise and experiences of our own dedicated Applications Engineering team, we detail the steps of a DOE and provide a core understanding of DOE basics — such as the difference between controllable vs. uncontrollable (noise) variables. You’ll also get examples of how a DOE can benefit your operation — from saving time and money at start-up to creating standard operating procedures for your machine operators. And you’ll see some samples of actual DOE analysis results and learn how to interpret the plotted findings.

Learn the basics of DOEs and why you should be using them to your advantage by watching our “Design of Experiment (DOE)” webinar today. Click here to download.