Quite the life-saver

Published on May 26, 2020

Reliable rolls are key for nonwovens manufacturers trying to meet demand for Covid-19 PPE products

Back in January, had you asked someone what “PPE” was, they may have guessed it was some sort of text abbreviation. Or maybe a new boy band. Today, though, it’s a term we’re all too familiar with. Covid-19 makes PPE — personal protective equipment — a term heard almost every day. On the news, websites, social media.

As the Corona virus outbreak has spread across the world, medical suppliers have experienced a massive increase in demand for PPE products, particularly N95 facemasks. You may remember the news story back in early March about the New York hospital that typically used 10,000 to 20,000 N95 facemasks per week, needing 300,000 per week to care for the rush of Covid 19-infected patients. A 3000% increase. At just one hospital.

This astounding demand for facemasks — as well as respirators, protective healthcare apparel, even anti-bacterial and disinfecting wipes — continues to surge. And as it does, so does the need for the nonwoven materials to produce them.

Nonwovens manufacturers across the globe are stepping up to produce this life-saving equipment. They are running their equipment hard. Beyond what is was designed to do. 24/7. Many are adding new machinery to help meet demand. And producers from related industries are converting their operations to contribute to the effort, too. To keep all these machines up and running as long and efficiently as possible, proper roll maintenance is a must.

We here at Precision Roll Grinders are no stranger to long-running rolls. Nor the nonwovens industry. We’re experts at extending the life of engraved rolls, smooth steel and nylon calender rolls, oil-heated anvil rolls, Hot S rolls, even Tokuden electrically heated rolls. From grinding and rebuilding … to the internal cleaning of oil-heated rolls, balancing and pin repair on engraved rolls — we’ve seen it and serviced it all.

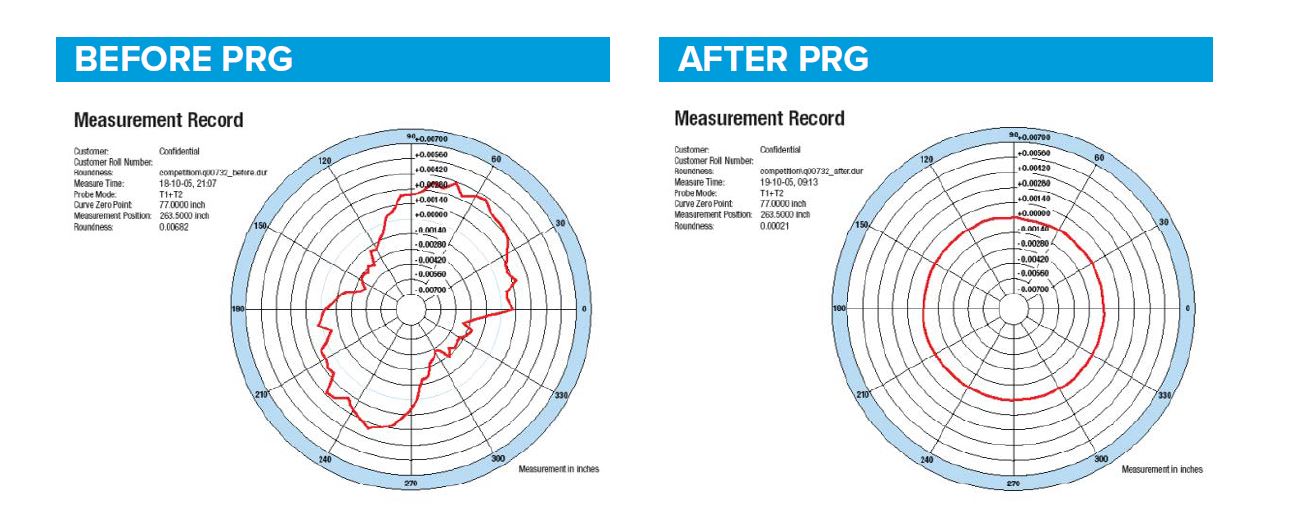

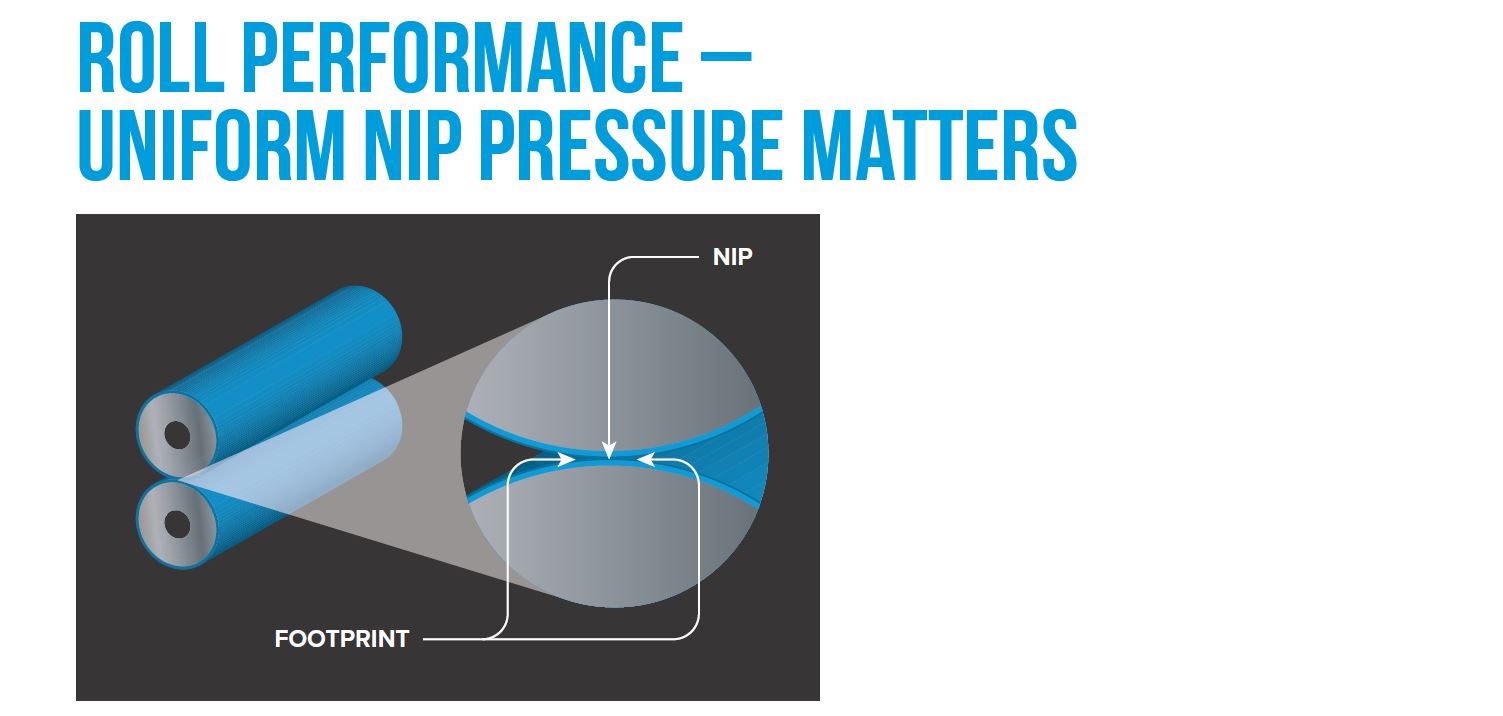

We know that the precision that goes into the roundness of these rolls is extremely critical —as is the proper shape of the rolls. But when it comes to nonwovens, perhaps nothing’s more important than heat transfer and uniform nip. And here is where we can have the most impact on your rolls.

Are you throwing away product because you’re not getting the right kind of thermal bond? Or slowing down your machines to achieve satisfactory bonds? The problem lies with your rolls — the thermal bonding that occurs in the calendaring of your product. And the answer is Precision Roll Grinders. We’ll solve this issue and more. And provide you with rolls that run longer. Up to three times longer than competitive grinds in fact. For a more in-depth look at the overall value we bring to nonwovens manufacturers, we encourage you to watch our webinar “Maximizing your Non-Woven Quality and Productivity.”

Download our Nonwovens Webinar or watch the recorded video below.