WEBINAR - How Paper Machine Calender Roll 'Barring' Hurts Your Bottom Line

Published on May 19, 2021

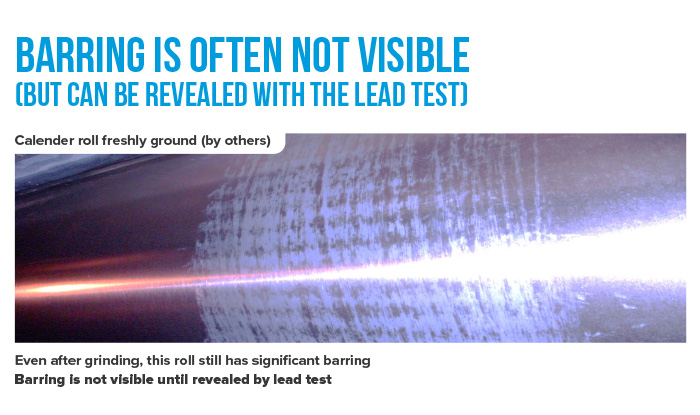

Barring may not be visible.

But you can see its negative effects on your bottom line.

It may be quietly hiding within your paper machine. Causing seemingly inexplicable runnability issues like slower run speeds and increased material usage. And resulting in sub-standard product coming off your line. It’s an issue known as barring: hard-to-detect peaks and valleys in your calender rolls that prevent you from manufacturing the best product possible. And it costs you money.

In our latest webinar, “Barring in Calender Rolls” we look at this sneaky and costly nuisance lurking within many paper machines. We explain why barring occurs, how it affects your machine and paper product, what you can do to detect it, and most importantly, how you can resolve it.

You’ll hear about what produces the vibration which is ultimately responsible for barring — in particular, poorly ground calender rolls. See what barring actually looks like and learn the four ways you can test your rolls to discover if barring is present. Understand the correlation between properly ground rolls and the elimination of barring. Discover why you need to grind all your rolls — even if only one shows evidence of barring — to prevent it from spreading. And much more. Get expert analysis, proven data and insightful tips to help you recognize, resolve and prevent barring.

Then, referencing customer case studies, we detail the savings we helped manufacturers achieve by eliminating barring from their calendar rolls. Paper savings of 1,000 tons a year … cost savings of $300,000 per year … reduction of winder breaks resulting in $100,000 of savings a year … all achieved with rolls precisely ground to very tight tolerances.

If you’re plagued with recurring problems like poor paper strength, short roll life, poor winder runnability — and can’t figure out what is the cause — you should check out our “Barring in Calender Rolls” webinar today to discover if barring is to blame. Click here to download.