WEBINAR - Precision Rubber Calendering - The Case For Huge Raw Material Savings

Published on February 26, 2021

Remove your rubber calender rolls for grinding

And see a bounce in material and money savings

We get it. Some things are a huge pain to do the right way. But, in the end, the results are completely worth it.

Take for instance, sharpening the blades on a riding lawnmower. Yeah, it’s a bit of an ordeal, but if you want a lawn that looks as good as the third hole at Augusta, you need to do it. Removing the deck, then removing the blades, sharpening them, balancing them, then repeating the entire process in reverse — it’s no walk in the park. Sure, you could try them while they’re still on the mower, but it’s not suggested. Plus, there’s no way for you to balance them on the mower. So, you end up with blades that cut not as well as they should; will need to be redone again soon; and vibrate terribly, slowly damaging your mower in the process.

The same’s true for maintaining your rubber calender rolls. Yeah, it’s a Herculean effort in some cases to remove the rolls from the calender to have them properly ground. But that’s how they’re supposed to be serviced. And grinding them this way will not only reduce the amount of costly material for your operation — it can actually pay for itself in a matter of weeks or a couple of months (then put additional savings back into your business. Results as satisfying as a perfectly manicured lawn.

In our latest webinar, “Precision Rubber Calendering: The Case for Huge Raw Material Savings” we draw upon our findings from 50+ years of industry experience to prove the value that proper roll grinding can bring to a rubber producer. You’ll learn how precision ground rolls — rolls that have the correct roundness, shape AND concentricity to meet or exceed OEM specifications — deliver significant savings, particularly by reducing material waste.

- Discover the valuable role the calender plays in rubber production

- Understand the relationship between uniform sheet thickness, uniform roll temperature, machine direction caliper and perfectly round rolls.

- Learn the direct effect that the roll’s profile has on the product profile and how improving the profile of the roll can result in huge material savings

- See why perfectly round rolls last longer, extending the time between grindings while still producing quality product

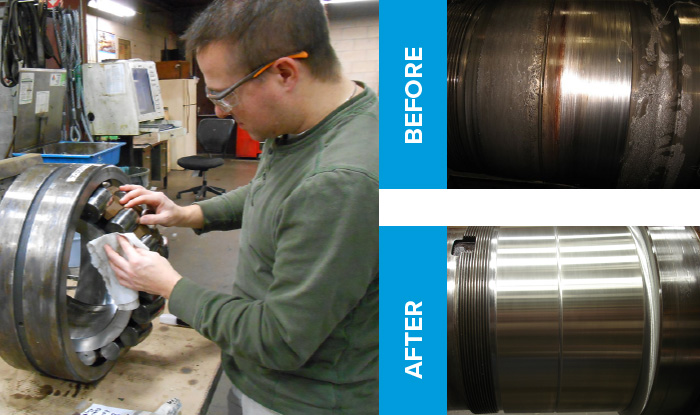

- Know the substantial differences between block grinding and off-machine roll grinding to explain why block grinding should be avoided

- And much more.

Then hear about PRG rubber-producing customers who chose to have their rolls removed and ground — and the substantial ROI they got on their roll-grinding investment. Shared case studies document how scrap reduction and longer roll life resulted in $500,000 yearly savings for one customer and highlights ROIs that were so substantial, customers actually bought spare calender rolls to have on hand at their facilities.

Find out if you're getting the maximum optimization and efficiency out of your rubber calender and are minimizing material costs — watch our “Precision Rubber Calendering: The Case for Huge Raw Material Savings” webinar today below or click here to download it.