Webinar - Rubber Industry

Published on June 9, 2020

It’s not a stretch to say rubber manufacturers love our rolls

For as many bad puns as there are about rubber, there are even more reasons why rubber producers repeatedly return to us for our grinding and roll services. Let’s bounce a few off of you, shall we? (Sorry, we just couldn’t help ourselves.)

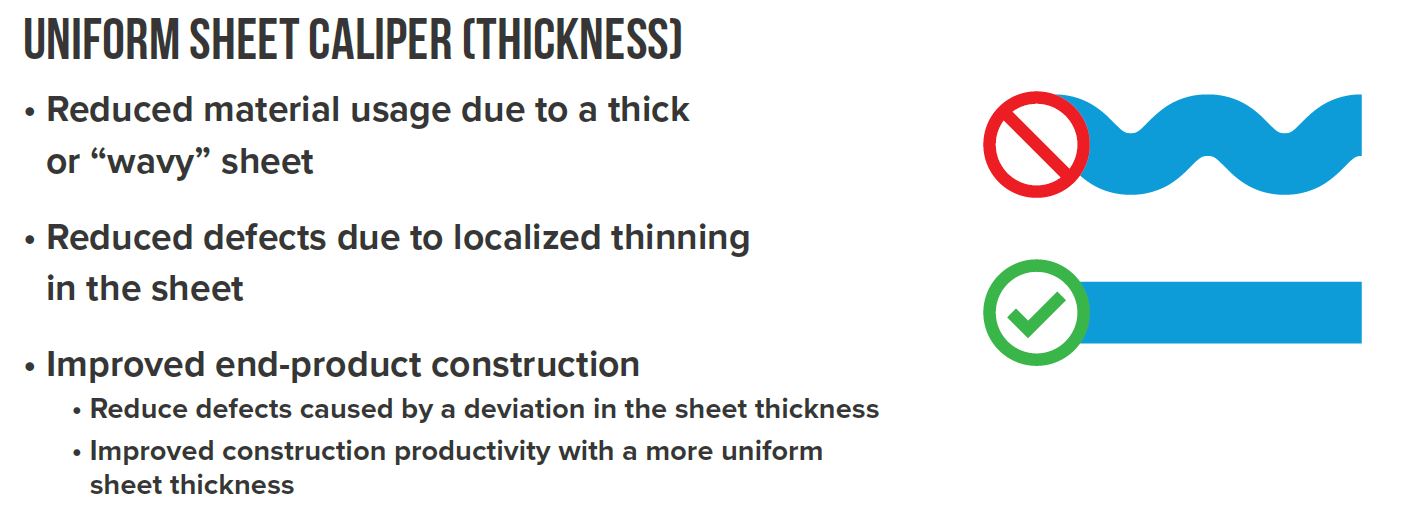

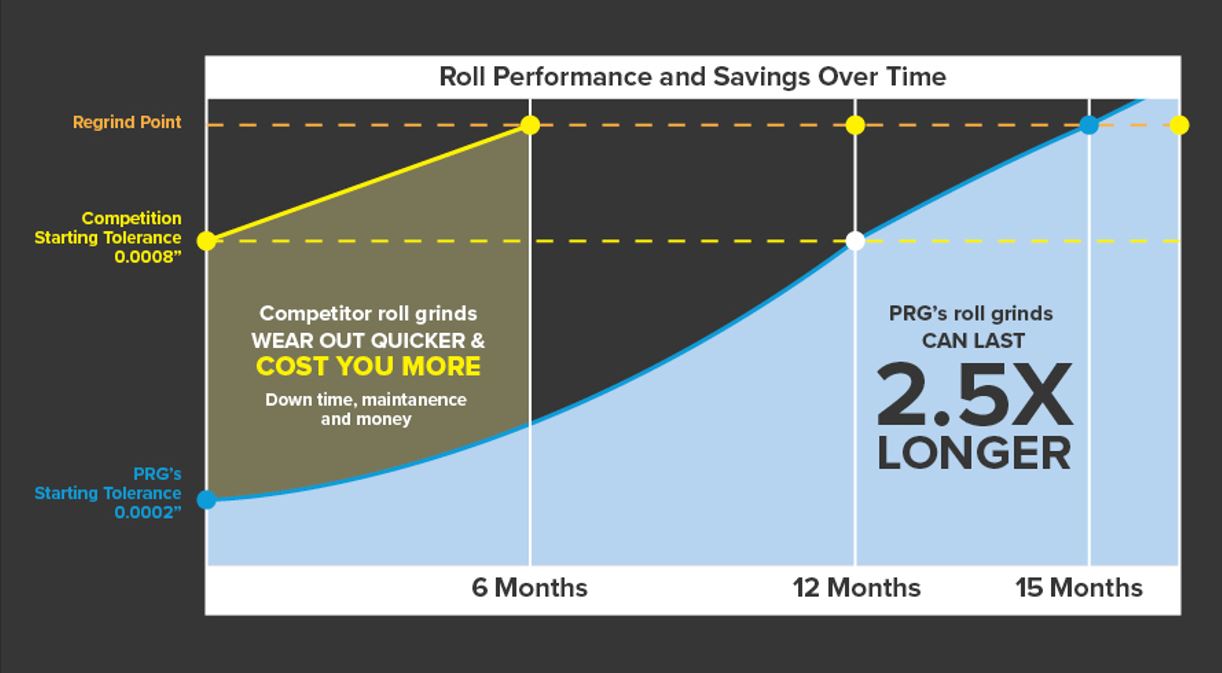

First and foremost, our properly ground rubber calenders and rubber calender rolls eliminate product errors and materials waste. Both of which save money. Here at PRG, we grind your rolls to the tightest tolerances in the industry — the tolerances required to achieve the minimum thickness for maximum product quality and products. Our thousandths of an inch are going to save you hundreds of thousands of dollars.

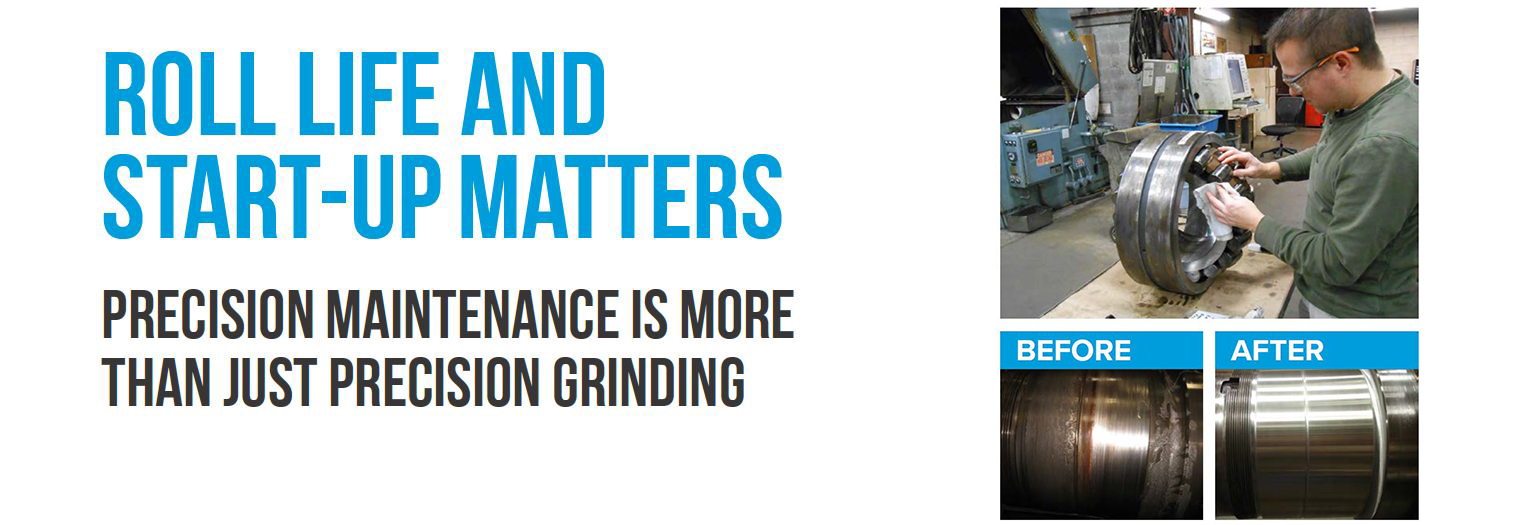

Our exceptionally round rolls do more than provide a consistent product, however. They reduce the wear on machines — wear that creates unnecessary chatter, vibration and more. Rubber rolls serviced by PRG keep machinery running at top condition. Because of their roundness — yes. But also because our roll services go beyond just precision grinding. Our roll maintenance takes a holistic look at your rolls. It involves looking at closures, properly retorquing the internals of the roll, cleaning interior fluid passages, even repairing roll surfaces if there are damaged areas. All of which benefit the roll and the machinery in which they run.

Then there’s the fact that we only perform off-machine roll grinding. This type of grinding is far better than block roll grinding when it comes to the rubber industry. Block grinding is done in bearings on the machine — which does not produce rolls that meet the original specifications. If something is off on one side or anywhere on the roll, it can’t possibly attain proper shape, roundness and TIR. Our off-machine grinding, on the other hand, allows the MD to be optimized, eliminates variation in CD caliper and produces a calendered sheet that is absolutely uniform.

Lastly, PRG-serviced rubber calender rolls keep machinery running at top condition for longer periods of time. Because we grind to the tightest tolerances, our rolls are proven to last longer — far beyond what you can expect from competitor-serviced rolls. You’ll find that using PRG easily pays for itself and then some. Actually more than just “some” — a lot. Especially when you factor the reduction in material waste and production errors into the savings as well.

For a more detailed discussion, including specifics on how we saved one rubber customer more than $500,000 a year, we invite to watch our insightful webinar, “Rubber Material Savings Through Precision Roll Grinding.”

Download our Rubber Industry Webinar or watch the recorded video below.