White Paper - Stop throwing money out with your soybeans

Published on November 8, 2020

Every year, manufacturers throw away $7-$16 million in inefficiently crushed soybeans. Are you one of them?

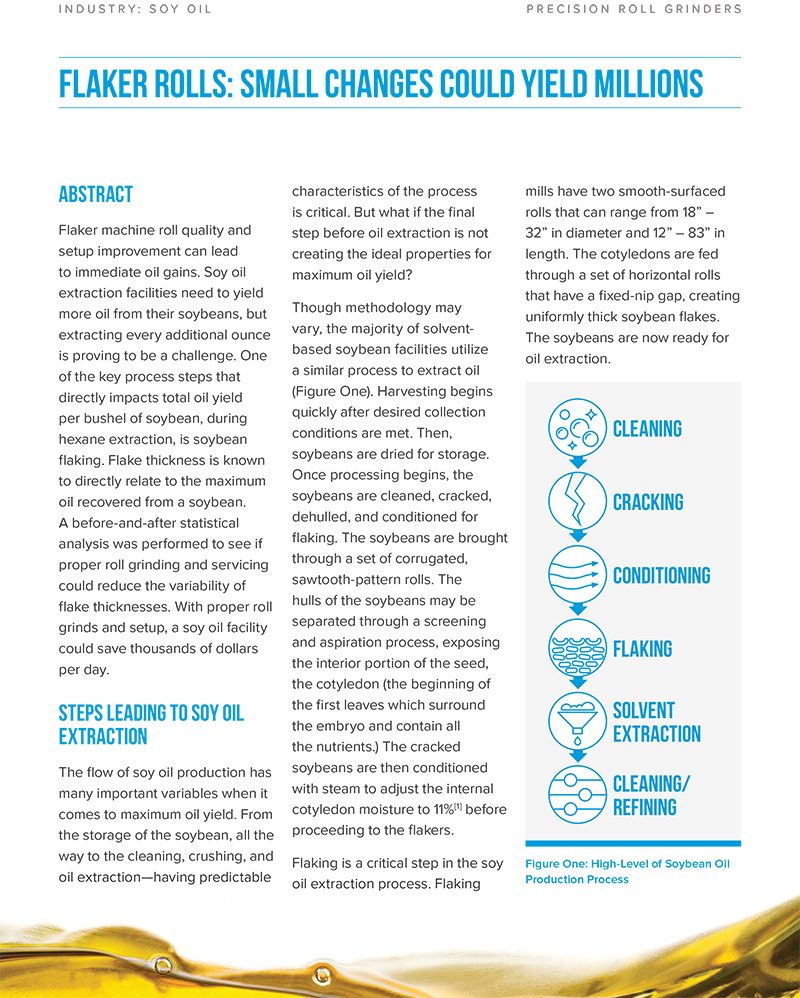

Flaking machines have one of the most important jobs of the soybean oil extraction process – ultimately determining how much oil can be extracted from a soybean.

This is because flake thickness directly relates to the maximum oil recovered from a soybean. When processed soybean oil flakes aren’t in spec, residual oil is left within each flake, and is ultimately discarded — along with lost revenue.

Seeing as 72 percent of all processed soybean oil flakes are out of spec — yours most likely are, too. Which means you are literally throwing money away along with your crushed flakes.

In its must-read white paper “Flaker Rolls: Small Changes Could Yield Millions,” Precision Roll Grinders validates how flaker machine roll quality and setup improvement can lead to immediate oil gains.

The paper takes a deep dive into a 5-week, before-and-after statistical analysis that determined proper roll grinding and servicing yields a variability reduction of over 34 percent, and reduces the number of flakes out of spec from 92 to 50 percent. Both of which led to an additional production profit of $2,000 per day for the company that was the subject of the analysis.

Additionally, “Flaker Rolls: Small Changes Could Yield Millions” examines how flakers and flake anatomy affect one another, and dissects the common problems plaguing flaker rolls and why they lead to profit-draining flake variation. The paper also poses the five steps you should be taking — and five questions you should be asking — to check for proper flaker setup at your facility.

Discover how you can increase your production profitability through properly ground, serviced and maintained flaker rolls. Download a copy of PRG’s insightful "Flaker Rolls: Small Changes Could Yield Millions" white paper today.

Download Whitepaper