Webinar - We're positive — Our calender rolls produce better-performing lithium-ion batteries

Published on May 5, 2021

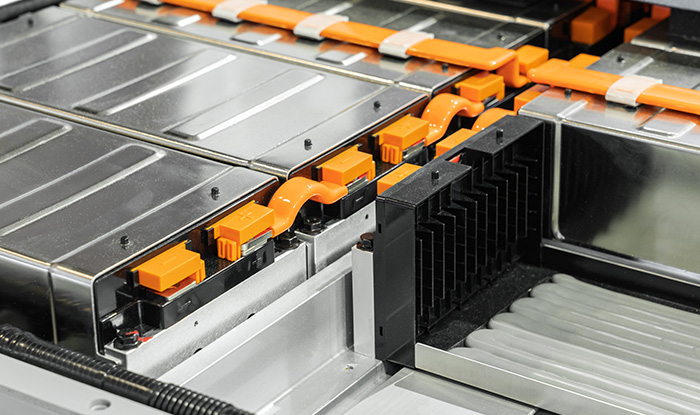

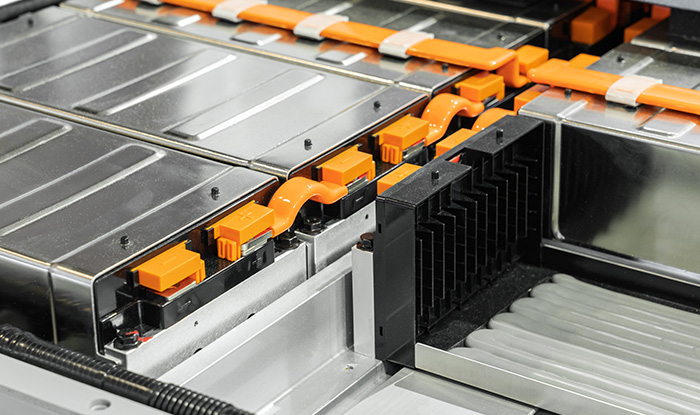

Calender rolls play a vital role in making everything from paper and cardboard to chocolate and rubber. But when it comes to the manufacturing of more sensitive products like lithium-ion batteries, the impact they have on the production process cannot be emphasized enough.

Quite simply, battery performance life is significantly influenced by the calender rolls in your machine. This is because the electrode coating compaction process requires extreme grind tolerances on calender rolls — up to 40 millionths of an inch — to create a quality electrode that guarantees proper functionality and performance in a battery. In other words, the quality of your rolls will ultimately determine the quality of the batteries.

Precision Roll Grinders is the only roll grinding and service provider in the world that has the capabilities to grind rolls to the required tolerances of modern-day battery manufacturers. We have the highest grinding tolerances in the world. Our equipment and skilled personnel guarantee that your company is getting the best possible grind to improve your lithium-ion battery manufacturing process.

The rolls you receive from us are serviced and ground to the proper roundness, TIR, and surface finish — the critical roll factors that will improve your battery production in several important ways. These three key areas of improvement not only result in a better performing battery, but also $100,000s in cost reduction and combined profit.

Production line efficiency

With the proper TIR and surface finish, calender rolls have a more uniform nip. Electrode calendering adjustments become less difficult and overall part-to-part variation is reduced. This adds up to more run time and the production of more quality electrodes.

Material usage

The result of an improved product profile means less scrap and a reduction in raw material costs. Less calender scrap also means greater efficiency coating as less coated material is scrapped after calendering.

Battery cell performance and life

In-spec calender rolls yield improved electrode caliper variation, and reduced porosity variation leading to better wettability. The variation reduction also improves packaging. This improves not only the battery’s energy density, but also the charge/discharge rates and cycle life.

To learn more, contact Precision Roll Grinders today.

Quite simply, battery performance life is significantly influenced by the calender rolls in your machine. This is because the electrode coating compaction process requires extreme grind tolerances on calender rolls — up to 40 millionths of an inch — to create a quality electrode that guarantees proper functionality and performance in a battery. In other words, the quality of your rolls will ultimately determine the quality of the batteries.

Precision Roll Grinders is the only roll grinding and service provider in the world that has the capabilities to grind rolls to the required tolerances of modern-day battery manufacturers. We have the highest grinding tolerances in the world. Our equipment and skilled personnel guarantee that your company is getting the best possible grind to improve your lithium-ion battery manufacturing process.

The rolls you receive from us are serviced and ground to the proper roundness, TIR, and surface finish — the critical roll factors that will improve your battery production in several important ways. These three key areas of improvement not only result in a better performing battery, but also $100,000s in cost reduction and combined profit.

Production line efficiency

With the proper TIR and surface finish, calender rolls have a more uniform nip. Electrode calendering adjustments become less difficult and overall part-to-part variation is reduced. This adds up to more run time and the production of more quality electrodes.

Material usage

The result of an improved product profile means less scrap and a reduction in raw material costs. Less calender scrap also means greater efficiency coating as less coated material is scrapped after calendering.

Battery cell performance and life

In-spec calender rolls yield improved electrode caliper variation, and reduced porosity variation leading to better wettability. The variation reduction also improves packaging. This improves not only the battery’s energy density, but also the charge/discharge rates and cycle life.

To learn more, contact Precision Roll Grinders today.